Pipes transport the drinking water from its source to the stable. The source may be a well or a commercial supplier. A control unit is usually placed at a central point in the building and consists of the water supply pipe, a water filter, a bypass, a pressure regulator and a water meter. All the necessary control equipment is installed here as well as any medication equipment. Make sure that it is easily accessible. All operations required to prepare solutions and switch from regular to medicated drinking water for each individual animal compartment are managed from the control unit.

The water meter measures the amount of water consumed by the animals. A dosing device can be installed just behind the water meter. In case of an electronic dosing pump, the water meter is included in the pump. The actual drinking water system begins just behind the dosing device.

It is important that the system has a separate line for medicated water; this is called a double system. It should allow medication by individual compartment (not just for the whole barn) which can be done using handles for each compartment in both the water and mediation line.

To prevent biofilm formation the pipes should have a linear flow with sufficient speed. This is achieved by:

Turbulence can cause deposits and biofilm, which may drastically reduce the supply of water to the animals and affect the success of any water medication.

When installing or renovating a drinking water system, we strongly recommend to engage a company that has relevant expertise in animal drinking water systems.

For more details on the different elements of a successful drinking water system, please read our Practical Guide for drinking water medication.

Click on the image to download a preview or contact your local Dechra representative to order a full copy.

Drinking water system maintenance

It is very important that you regularly maintain the drinking water system to keep it functioning properly. One of the major points here is cleaning and disinfection.

Immediately after each drinking water medication, routine cleaning and disinfection is required using a low concentration during 48 hours. Additionally in all in all out facilities you should use a high dosage during 12 hours each time the pens or stables are empty.

Permanent housing systems will always have animals. In this case you should use a low dosage for a longer period (5 days) every 3 months.

General guideline:

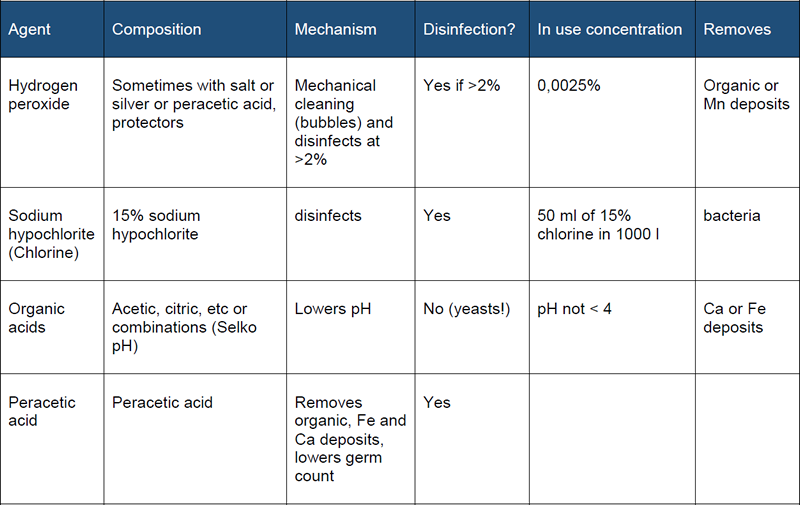

Chlorine is best used after hydrogen peroxide

Always consult the product supplier for optimal use and correct dosage!

In general, it is very important to clean and disinfect drinking water systems regularly, preferably every time the stable is empty. This will prevent potential problems such as clogged pipes and drinking nipples.

In addition, water systems should be cleaned and/or flushed before and after the use of medication. This will ensure that the pipes are clean when a new round of medication is administered and that no residue is left behind that could turn into biofilm over time.

Several specialised products are available for proper cleaning and disinfection of pipes. A survey on drinking water and drinking water medication use reveals that livestock breeders clean the pipes with chlorine, organic acids, peracetic acid and/or cleaning agents based on hydrogen peroxide.

If you have any questions please go to the support page to get in touch.